| Author |

Message |

Jersey_Boy

Citizen

Username: Jersey_boy

Post Number: 870

Registered: 1-2006

| | Posted on Saturday, May 20, 2006 - 9:31 pm: |

|

I just read an article in "Fine Homebuilding" about Polyethylene piping. It seems ideal for renovating with little tearing up of walls on your way to upper floors.

It's flexible not rigid, so you can snake it like wire. "It won't corrode or explode."

Anyone know about it? You plumbers out there, have you worked with it?

J.B. |

Dennis J O'Neill

Citizen

Username: Plungy

Post Number: 30

Registered: 6-2005

| | Posted on Saturday, May 20, 2006 - 9:53 pm: |

|

Haven't started with it yet but I am sure we are gonna have to sooner or later with the way copper prices have been sky rocketing lately. It is cheaper of course. It doesen't look as neat as copper when installed. The initial investment is a few hundred bucks due to all the specialty tools, ring krimpers ect. you have to buy. It is widely used in new construction already. |

Jersey_Boy

Citizen

Username: Jersey_boy

Post Number: 872

Registered: 1-2006

| | Posted on Saturday, May 20, 2006 - 10:48 pm: |

|

Doesn't look as neat as copper?

You should see the copper mess in my basement. Of course my basement still has lead pipes that were unhooked and left in.

Why not add PEX to the mish mash?

J.B. |

Dennis J O'Neill

Citizen

Username: Plungy

Post Number: 31

Registered: 6-2005

| | Posted on Sunday, May 21, 2006 - 8:46 am: |

|

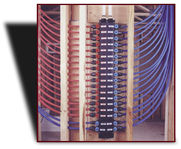

Oh yeah, I forgot to mention that every supply is a "home run" off a central manifold, typically in the basement as in J.B.s pic. So instead of one set of hot and cold risers to an upstairs bath you would have five. Lots of spaghetti.

J.B. is right though, there are some god awful copper jobs out there.

As I said, you can't stop progress and this stuff is the wave of the future. It WILL supplant copper eventually. |

doulamomma

Citizen

Username: Doulamomma

Post Number: 1431

Registered: 3-2002

| | Posted on Sunday, May 21, 2006 - 9:23 am: |

|

I think this is what was installed for the new stuff in my home - but it was opaque clear/white. This was late last summer/early fall. |

Master Plvmber

Citizen

Username: Master_plvmber

Post Number: 532

Registered: 3-2003

| | Posted on Sunday, May 21, 2006 - 10:02 am: |

|

We've been using PEX (polyethylene cross-linked) tubing for radiant floor heating for several years. There are several areas in the country, including NYC, where it is not approved for use with domestic water and so its use is limited to the heating trade.

I agree with Mr. O'Neill that we're likely to see more and more of it in the future but there are lots of people out there who still prefer copper for its rigidity and time-tested reliability among other reasons.

Master Plvmber |

Jersey_Boy

Citizen

Username: Jersey_boy

Post Number: 879

Registered: 1-2006

| | Posted on Sunday, May 21, 2006 - 1:08 pm: |

|

Dennis,

That's only one way to run it. You can also run lines up to several sub-manifolds with separate shut off valves. For example: run a hot and cold to each bathroom, then place a manifold in the floor there with separate branches. The article I read had three ways to lay the stuff out, and compared the water wasted waiting to run hot in each, so there's spagetti, but it can be hidden AND energy efficient.

Doulamamma,

That's PEX, it also comes in white. The blue and red are for simplicity of identifying the hot and cold.

So, if I wanted this stuff, who would install it?

J.B. |

Dennis J O'Neill

Citizen

Username: Plungy

Post Number: 32

Registered: 6-2005

| | Posted on Sunday, May 21, 2006 - 6:47 pm: |

|

I think that alot of us old farts in the trade may have a wait and see attitude about it due a disaster called Qest tubing. A forerunner of Pex that was used in many new homes in the early 90s. Contractors down south were going great guns with the stuff until the connections started blowing apart and causing millions of dollars in flood damage. Huge class action suit the works. We didn't see too much of it here except in some prefab homes that made it to our area and some trailers in Middlesex ect. I got to see the results first hand on a couple of jobs.

When we do start using it I know I'll be hesitant, at least at first, to bury connections in hard to get at places like under bathroom floors.

I think that talking to a contractor who does more new contruction as opposed to old home repairs would be the place for you to start. As for snakeing it like wire... to an extent, but be prepared to open walls and cielings just like a copper pipe installation. |

Travis

Citizen

Username: Travis

Post Number: 429

Registered: 6-2004

| | Posted on Sunday, May 21, 2006 - 7:10 pm: |

|

Hasn't PEX been in use in Sweden for at least 20 years? I have the impression it's all that Europeans use anymore.

Did the US insist on reinventing the wheel, or cutting corners, or was it lack of experience/training? |

Master Plvmber

Citizen

Username: Master_plvmber

Post Number: 533

Registered: 3-2003

| | Posted on Sunday, May 21, 2006 - 7:54 pm: |

|

Yes, it's been in use in Europe for decades. The problems we've been having with it here in the US is adapting it to our construction methods. Very little construction in Europe is done with wood or metal framing and nails and screws. They use lots of masonry materials.

Master Plvmber |

Bob K

Supporter

Username: Bobk

Post Number: 11590

Registered: 5-2001

| | Posted on Monday, May 22, 2006 - 4:06 am: |

|

I think Master Plvmber's last point is a good one. A lot of construction materials that work just fine in Europe, don't work as well here because of different weather conditions and construction techniques. Years ago my company was involved with a membrane roofing system that had worked fine in Europe for 25 years, but didn't last worth a darn in the United States.

My reading on PEX is that it would be great for remodeling because it is flexible and comes in long lengths. However, snaking it through walls might cause an abrasion problem or some other condition.

|

Travis

Citizen

Username: Travis

Post Number: 430

Registered: 6-2004

| | Posted on Monday, May 22, 2006 - 5:32 am: |

|

I don't see how wood vs masonry construction makes connections fall apart. |

Bailey

Citizen

Username: Baileymac

Post Number: 295

Registered: 3-2005

| | Posted on Monday, May 22, 2006 - 7:31 am: |

|

Maybe the sharp edges of holes punched in metal studs can cut pex over time, due to vibrations, and expansion and contraction of materials, but as Travis said, wood vs masonry shouldn't be an issue.

I used pex tubing for hydronic radiant heat in my daughter's house a couple years ago, and I can't believe we still heat new homes any other way. The floors are always warm, makes the house so comfortable.

Pex is ideal for that type of installation, but I used copper for all the water supplies, mostly out of habit, but more because I'm just used to using copper. Some plumbers are such craftsmen with copper pipe, it's almost hidden art, but some, not so much.

I design fire protection systems using a type of plastic piping called CPVC, which is also making its way into domestic water supply piping, so it's pretty obvious to me that plastic in one form or another will be the material of choice eventually.

|

Master Plvmber

Citizen

Username: Master_plvmber

Post Number: 534

Registered: 3-2003

| | Posted on Monday, May 22, 2006 - 8:06 am: |

|

It's not about the connections coming apart right now, it has more to do with heat transfer through various building materials and the effect of the chemical make-up of our domestic water on the tubing.

Master Plvmber |

Jersey_Boy

Citizen

Username: Jersey_boy

Post Number: 884

Registered: 1-2006

| | Posted on Tuesday, May 23, 2006 - 6:31 am: |

|

You mean their are chemicals in our water?!

Didn't CPVC have a snafu a few years ago with bursting?

J.B. |